GALLING RESISTANCE

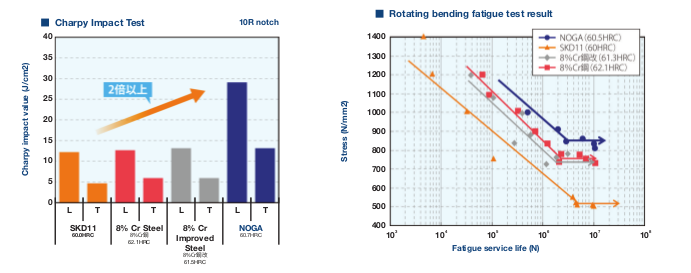

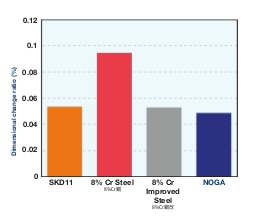

- Galling that occurs in high-tensile molding (adhesive wear due to rising of friction heat) is produced in a peeling postion of surface coating . NOGA combines the characteristics to resist galling by improving adhesion to surface coating

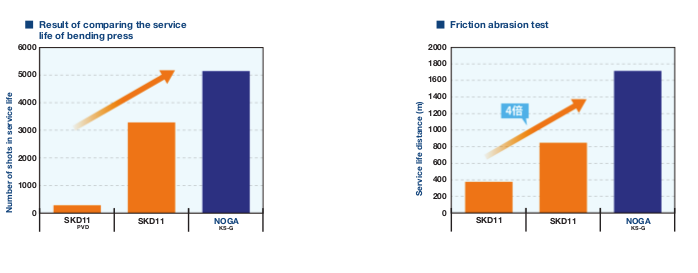

- NOGA improves service life amazingly further than SKD11 by the KS-G coating treatment

FOLLOW US