| JIS | AISI | WNr | DIN |

| SKD61 | H13 | 1.2344 | 1.2344 |

CHEMICAL COMPOSITION(Typical Analysis %)

| C | Si | Mn | P | S | Cr | Cu | Ni | Mo | V |

| 0.34 | 0.60 | 0.44 | 0.21 | 0.03 | 4.78 | 0.08 | 0.15 | 1.61 | 0.51 |

STEEL PROPERTIES

Hot work tool steel. Secondary hardening steel. Good tempering resistance. It maintains high hardness and strength at elevated temperatures.

Resistance to thermal fatigue, erosion and wear. Very high toughness. Good ductility and hardenability - air cooling. Tools can be water cooled

PHYSICAL PROPERTIES

Thermal coductivity W/(m.K) 20°C/25 500°C/28.5 600°C/29.3

Density g/cm3 20°C/7.78 400°C/7.64 600°C/7.60

Coefficient of linear thermal expansion

| 10-6 °C-1 | 20-100°C | 20-200°C | 20-300°C | 20-400°C | 20-500°C | 20-600°C | 20-700°C | 20-800°C |

|---|---|---|---|---|---|---|---|---|

| 10.7 | 11.9 | 12.2 | 12.5 | 12.7 | 13.1 | 13.5 | 13.7 |

APPLICATIONS

Wear resisting tools, pressure die casting tools, pressing tools for light and heavy metal.

For the highest requirement we recommend UTOPMO2 ESR EFS

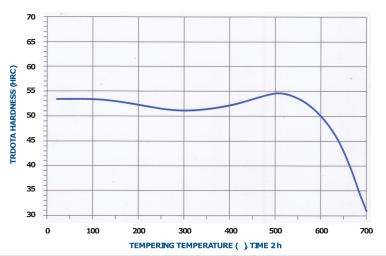

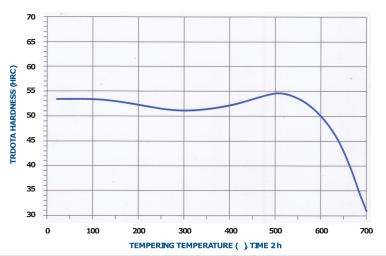

HEAT TREATMENT

| SOFT ANNEALING(°C) | COOLING | HARDNESS (HB) |

| 760-810 | FURNACE | MAX. 229 |

| HARDENING FROM(°C) | IN | HARDNESS AFTER QUENCHING (HRC) |

| 1020-1080 | OIL, AIR, THERMAL BATH 450-550°C | 52-56 |

| TEMPERING (°C) | 1000 | 1040 | 1080 | 1120 | 1140 | 1160 | 1180 |

| HARDNESS (HRC) | 57 | 59 | 61 | 63 | 64 | 65 | 65.5 |

| (N/mm2) | 1790 | 1730 | 1790 | 1910 | 1845 | 1680 | 1360 |

NITROCARBURISING AT 570°C X 2HRS (51 %NH3, 43%N2, 1% Propane)

| HRC AT COMPOUND LAYER | THICKNESS OF COMPOUND LAYER | THICKNESS OF CASE DEPTH | CORE HARDNESS (HRC) |

| 69 | 5 - 6µm | 190µm | 48 |

ADDRESS

PHH METAL 1 SDN. BHD.

Wisma PHH, Jalan PPU 3,

Taman Perindustrian Puchong Utama,

47100 Selangor,

Malaysia..

CONTACTS

Email: info@phh.com.my

: sales@phh.com.my

Telephone: +60 3 8068 7000

Fax: +60 3 8068 2020

LINKS

FOLLOW US