| SKD11 | AISI | WNr. | DIN |

| SKD11 | D2 | 1.2379 | 1.2379 |

CHEMICAL COMPOSITION (Typical analysis %)

| C | Si | Mn | Cr | Cu | Ni | Mo | V |

| 1.17 | 0.26 | 0.36 | 9.76 | 0.06 | 0.21 | 0.89 | 0.17 |

STEEL PROPERTIES

Ledeburitic Cr-steel for cold work. High wear resistance. Very good toughness, compression strength and dimensional stability. Nitriding capability

PHYSICAL PROPERTIES

Thermal coductivity W/(m.K) 20⚬C/20

Density g/cm3 20⚬C/7.69

Coefficient of linear thermal expansion

| 10-6 ⚬C-1 | 20-100⚬C | 20-200⚬C | 20-300⚬C | 20-400⚬C | 20-500⚬C | 20-600⚬C | 20-700⚬C | 20-800⚬C |

|---|---|---|---|---|---|---|---|---|

| 9.8 | 11.7 | 12.1 | 12.8 | 12.9 | 13.0 | 13.2 | 13.5 |

Application

High performance cutting tools, stamping-, woodworking-, moulding tools for plastics

Heat Treatment

| SOFT ANNEALING(⚬C) | COOLING | HARDNESS (HB) |

| 840-880 | FURNACE | MAX. 255 |

| HARDENING FROM(⚬C) | IN | HARDNESS AFTER QUENCHING (HRC) |

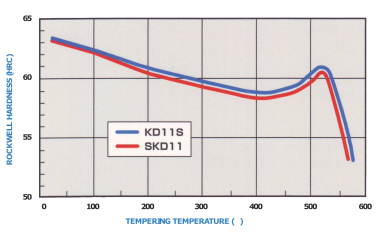

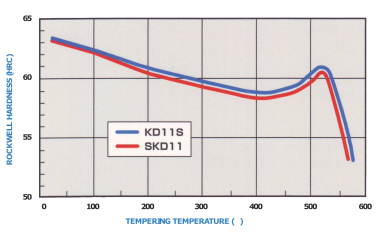

| 1020-1050 | AIR,OIL,WARM BATH 500-550⚬C | 62-64 |

ADDRESS

PHH METAL 1 SDN. BHD.

Wisma PHH, Jalan PPU 3,

Taman Perindustrian Puchong Utama,

47100 Selangor,

Malaysia..

CONTACTS

Email: info@phh.com.my

: sales@phh.com.my

Telephone: +60 3 8068 7000

Fax: +60 3 8068 2020

LINKS

FOLLOW US