| JIS | AISI | WNr | DIN |

| - | P20+Ni | 1.2738 | 1.2738MDF |

CHEMICAL COMPOSITION (Typical Analysis%)

| C | Si | Mn | Cr | Ni | Mo | S |

| 0.37 | 0.30 | 1.40 | 2.00 | 1.00 | 0.20 | ≤0.01 |

STEEL PROPERTIES

No hardening risks, no hardening costs and time saving (e.g, no waiting for heat treatment) including lower tool cost(e.g, no distortion to rectify),

modifications easily carried out, can subsequently nitrided to increase surface wear resistance or locally fame hardened to reduce surface damage

| Yield Strength(Mpa) | Tensile Strength(Mpa) | Elongation(%) | Compressive Strength |

| 1110 Mpa @ 340HB | 985 Mpa @ 340HB | - | - |

PHYSICAL PROPERTIES

Thermal coductivity W/(m.K) 20⚬C/29 200⚬C/30 400⚬C/31

Coefficient of linear thermal expansion

| 10-6 ⚬C-1 | 20-100⚬C | 20-200⚬C | 20-300⚬C | 20-400⚬C |

|---|---|---|---|---|

| 11.7 | 12.7 | 13.0 | 13.6 |

APPLICATIONS

Injection moulds for thermoplastics, extrusion dies for thermoplastic, blow moulds, forming tools, press-brakedies (possibly fame hardened or nitrided)

low-temperature die casting dies (e.g, tin, lead & zinc) structural components and shafts

| SOFT ANNEALING(⚬C) | COOLING | HARDNESS (HB) |

| 700 | FURNACE | MAX. 370 |

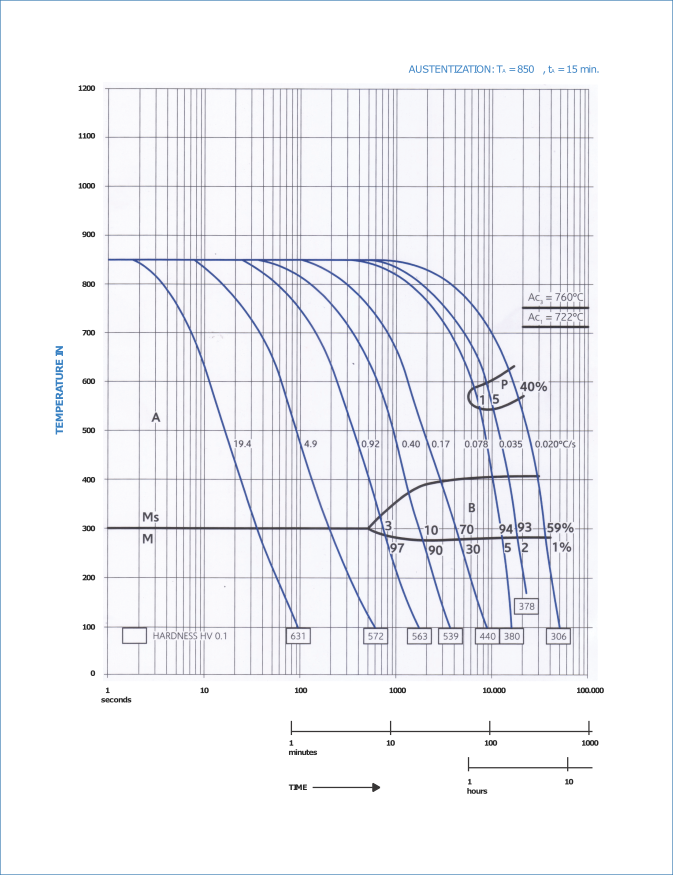

| HARDENING FROM(⚬C) | IN | HARDNESS AFTER QUENCHING (HRC) |

| 850-880 | OIL, AIR, THERMAL BATH | 50 HRC |

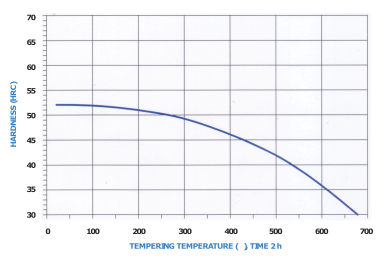

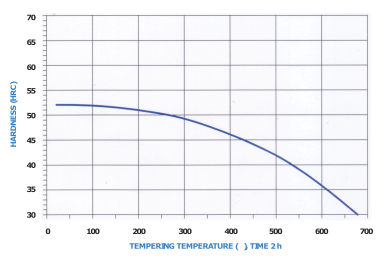

| TEMPERING (⚬C) | 200 | 300 | 400 | 500 | 600 |

| HARDNESS (HRC) | 52 | 50 | 47 | 43 | 37 |

NITROCARBURISING AT 570⚬C X 2HRS (51 %NH3, 43%N2, 1% Propane)

| HRC AT COMPOUND LAYER | THICKNESS OF COMPOUND LAYER | THICKNESS OF CASE DEPTH | CORE HARDNESS (HRC) |

| 63 | 10-12µm | 250µm | 33 |

ADDRESS

PHH METAL 1 SDN. BHD.

Wisma PHH, Jalan PPU 3,

Taman Perindustrian Puchong Utama,

47100 Selangor,

Malaysia..

CONTACTS

Email: info@phh.com.my

: sales@phh.com.my

Telephone: +60 3 8068 7000

Fax: +60 3 8068 2020

LINKS

FOLLOW US