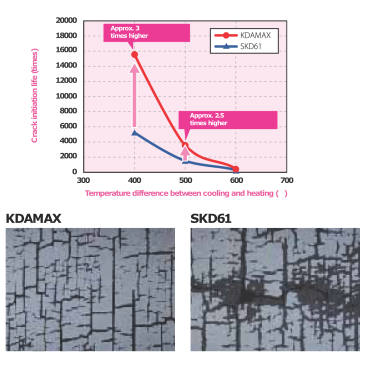

HEAT CHECK RESISTANCE

- The crack length of KDAMAX is 40% shorter than that of SKD61.

- The KDAMAX slows the expansion of the width of the cracks on the surface of the dies.

- Occurrence of heat check on the surface of the KDAMAX (47HRC)

- Relationship between the heat check initiation life and the temperature

Test conditions

- High-frequency heating from 100 to 600 (with a temperature difference of 500between cooling and heating)

FOLLOW US